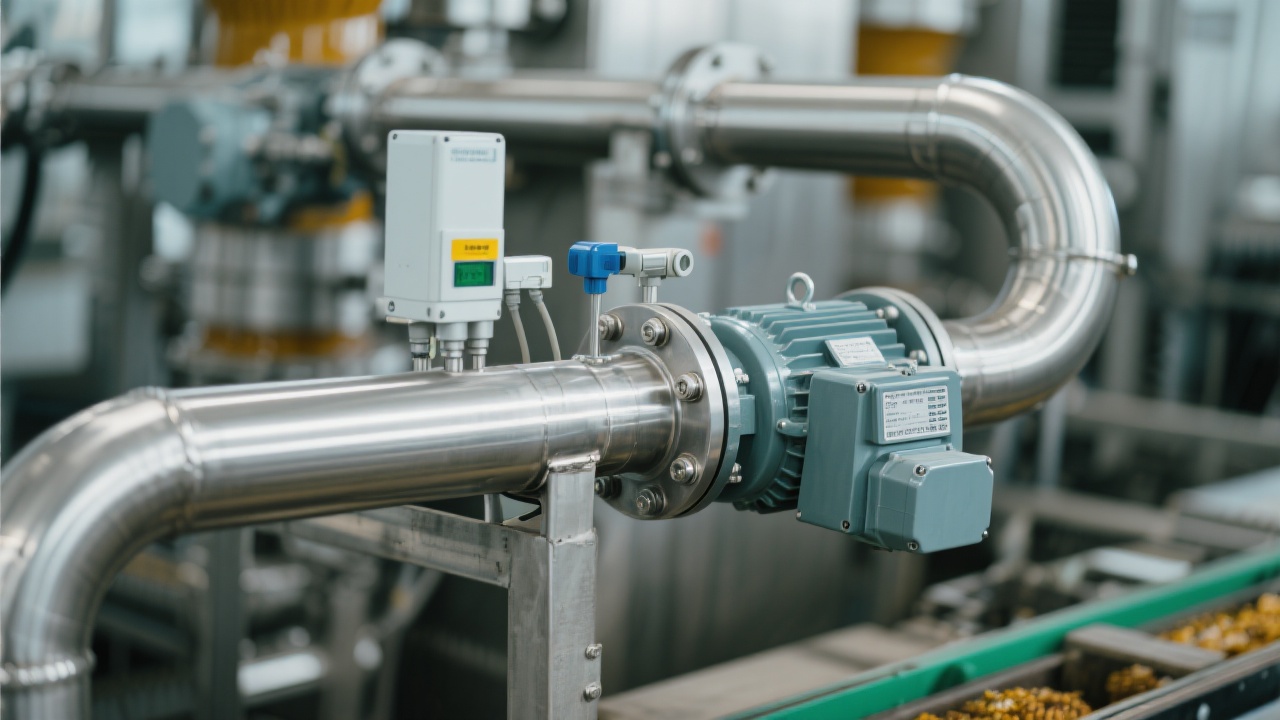

In the highly competitive grain and oil processing industry, especially among small and medium-sized enterprises (SMEs), operational reliability is paramount. As an engineer deeply involved in the design and manufacturing of Penguin Group’s automated palm oil processing equipment, I’m often asked: “What makes your core components robust enough to back a 36-month warranty?” Today, I invite you to explore the material science, manufacturing precision, and rigorous testing protocols behind this commitment — all designed to reduce your annual downtime, slash manual labor dependency, and optimize energy utilization.

SMEs in the grain and oil sector frequently wrestle with high operational costs due to equipment failure, excessive maintenance, and intensive labor needs. Industry data reveals that traditional manual or semi-automated machines require 3 to 4 times more frequent maintenances annually than automated models. Each maintenance event typically leads to an average of 16 to 24 hours of downtime, significantly impacting production schedules and profitability.

| Equipment Type | Avg. Maintenance Frequency (per year) | Avg. Downtime per Event (hours) | Manual Labor Requirements |

|---|---|---|---|

| Traditional Manual Equipment | 6-8 | 18-24 | High (3-4 operators) |

| Penguin Group Automated Equipment | 2-3 | 8-12 | Low (1 operator) |

Reducing these pain points requires a core focus on achieving exceptional component reliability.

Our 36-month warranty guarantee hinges on three core pillars:

By combining these strategies, we minimize mechanical stress, material degradation, and friction losses, ensuring long-term durability that justifies our warranty promise.

“Using premium AISI 316L stainless steel in harsh processing environments is not just a choice; it’s a necessity for sustained reliability and food safety. Our testing environment replicates real-world cycles, so our clients never face unexpected downtime.”

— Lead Engineer, Penguin Group

Apart from hardware, our integrated smart control systems play a vital role in operational excellence. Real-time monitoring sensors track torque, temperature, and vibration. Any deviation outside predefined thresholds triggers automatic adjustments or alerts—for example, when motor load exceeds safe parameters, the system reduces speed to prevent damage.

This approach lowers manual intervention needs and preempts unexpected breakdowns—key factors for SMEs with limited maintenance teams.

Equally critical is our comprehensive international support infrastructure. With strategically located spare parts depots and trained service personnel across Asia, Africa, and Latin America, clients benefit from:

In real-world terms, one Indonesian palm oil SME customer reported a reduction in annual downtime hours from 150 to under 50 after upgrading to our automated solution — translating into a significant improvement of operational efficiency and ROI.

In essence, the upfront investment in high-quality automated equipment paired with durable core components pays off through:

Choosing equipment with a verifiable 36-month warranty gives you peace of mind and a competitive operational edge.

Consider a mid-sized palm oil processor in Malaysia who transitioned from a manual system to our automated line equipped with 316L stainless steel core components. After 18 months:

This clearly demonstrates how deliberate materials and engineering decisions reflect directly on operational KPIs and profitability.